Deburr 100 Complex Edges in Seconds: A Smarter CAM Strategy for SYIL Users

Stop hand-deburring. Use an automated chamfer/deburr toolpath to finish dozens (even hundreds) of edges in a single cycle—fast, consistent, repeatable.

Manual deburring is slow, fatiguing and inconsistent—especially on multi-feature parts with pockets, bosses, and tight internal corners. In this guide, we break down a CAM-driven deburr strategy that lets you chamfer and break sharp edges automatically across a whole part, turning minutes of bench work into seconds of spindle time. Inspiration: Titans of CNC’s walkthrough on high-volume deburr toolpaths.

Why move deburring into the machine?

-

Speed: Deburr dozens of edges in one cycle—no part handling between ops.

-

Consistency: Uniform chamfer width/edge break across every feature and every part.

-

Safety & quality: Less hand work = fewer slips, scratches, and variability.

-

Throughput: Free your operators to run more machines or prep next jobs.

The core idea (that makes it “seconds,” not minutes)

Most modern CAM systems include a Deburr/Edge Break/Model-based Chamfer toolpath. Instead of clicking each edge, you select bodies or faces and set a target chamfer size. The CAM automatically finds edges, respects contact limits, and follows them with an appropriate tool.

Typical tooling options:

-

Chamfer mill (easy to program, crisp chamfers)

-

Ball end mill (gentle edge breaks, great on organic/complex geometry)

-

Lollipop/deburr cutters (reach past lips/overhangs)

Pro tip: Start with a small programmed chamfer (e.g., 0.1–0.3 mm / .004–.012”) and validate on scrap—edge breaks read larger on soft alloys and smaller on tough steels.

Step-by-step: Deburr in your SYIL (X7/X9, etc.)

1. Model sanity check

-

Suppress fillets you don’t want to cut; freeze critical sharp edges you do want to break.

2. Choose the toolpath

-

Use your CAM’s Deburr/Edge Break strategy. Target a small constant width.

-

Enable automatic edge detection on selected bodies/faces.

3. Pick the tool

-

Start with a 60–90° chamfer mill for general work.

-

Use ball or lollipop when geometry is contoured or access is limited.

4. Set engagement rules

-

Contact only on outside edges (avoid internal bores unless intended).

-

Stay-down linking to reduce retracts = faster cycle.

5. Feeds, speeds, depth

-

Aim for light radial engagement with higher feed.

-

Program chamfer width, not depth; let the CAM compute Z.

-

For tougher materials (e.g., 4140 HT), keep SFM moderate, feed brisk, and use flood/air blast for chip evacuation.

6. Simulate & filter

-

Exclude edges near delicate features (o-ring grooves, thin walls).

-

Add avoid surfaces where fixtures/clamps are close.

7. Prove-out

-

Run a verification pass in air, then on a scrap part.

-

Measure chamfer width on a few representative areas; adjust once.

Tooling & set-up tips for compact VMCs (SYIL sweet spots)

-

Short stick-out = better finish, fewer “witness marks.”

-

High-positive inserts (for face mills used pre-deburr) reduce cutting forces on smaller spindles.

-

ATC ordering: Call deburr late in the cycle—right before washdown—so parts leave the machine “bench-ready.”

Common pitfalls (and how to avoid them)

-

Over-breaking edges: Start tiny; increase only after measuring.

-

Hitting fixtures: Use stock/fixture models and “keep-away” surfaces.

-

Missed recesses: Switch to a ball or lollipop tool and allow surface following, not just edge tracing.

-

Burrs returning: For gummy alloys, raise surface speed slightly and increase feed; sharp tools matter more than anywhere else.

Quality check: fast and objective

-

Chamfer gauge or microscope reticle to spot-check width.

-

Edge feel (glove test) should be uniformly smooth—no “tooth” across transitions.

-

Record tool life at this light-engagement op; it’s usually excellent.

What this means for your SYIL workflow

-

Cycle time down, part consistency up—ideal for X7/X9 batch work.

-

Operator hours shift from finishing to value-added changeovers and in-process QC.

-

Easier to scale to lights-out: deburr is deterministic, bench work is not.

Ready to try it?

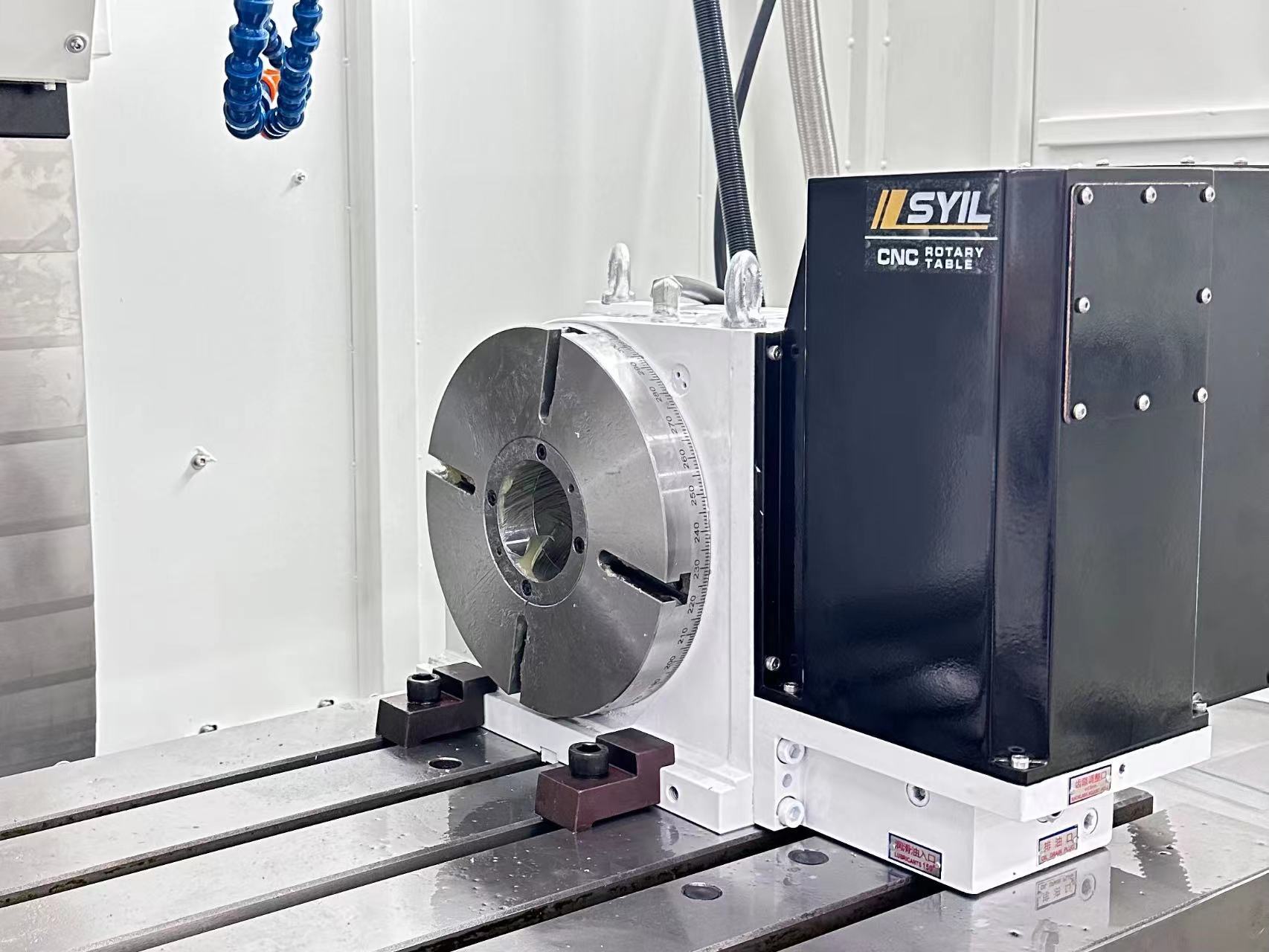

If you’re running a SYIL X7, X9, or L-series, we can help you implement a deburr toolpath into your current posts and templates—so every program finishes with clean, consistent edges.

Book a demo · Ask for a CAM template · Get a quote

Watch the video or visit: https://www.syil.com/x9.